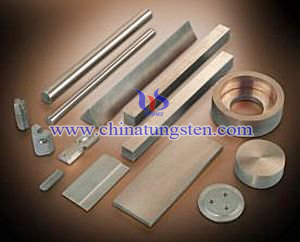

Silver Molybdenum Electrical Contacts

We offer a series of tungsten silver compositions with the tungsten content ranging from 10% to 88% by weight. Tungsten has the highest strength and the highest melting temperature of the refractory metals. This is the principal factor in determining a contact's resistance to arc erosion and mechanical wear. The strength, erosion and weld resistance characteristics of the contact increase with increasing tungsten content; the electrical and thermal characteristics decrease. In selecting a material composition for a given application, you choose the highest refractory content that will provide a satisfactory temperature rise and current interruption.

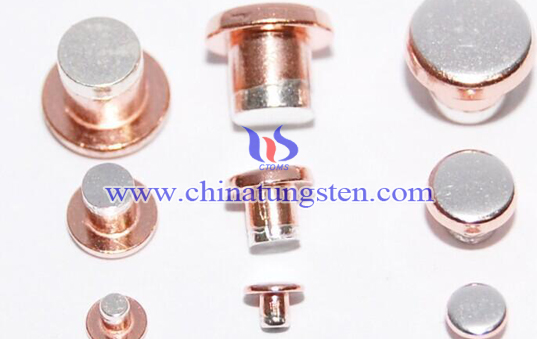

Silver molybdenum electrical contacts which are composited by 73W27Ag (by weights) are made by press-sinter-infiltration and normally a high resistance to arc erosion. It is generally used as arcing contacts in large air and oil circuit breakers, line disconnects, re-closures, and in high current switches and contactors. Contact resistance is low enough to protect the higher conductivity current carrying contacts from arc damage. Its resistance to welding makes it a good shorting contact for bimetal protection in circuit breakers.

The silver molybdenum electrical contacts which is composited by 70W30Ag (by weights) and 65W35Ag (by weights) have more silver than 73W27Ag (by weights), which provides higher conductivity and a lower contact resistance. They are used extensively in a large variety of circuit breakers. In this application, a single pair of contacts provides the dual function of carrying the current without overheating, and interrupting the current without excessive arc erosion. They are also used in high current contactors where resistance to contact welding and arc erosion are required. In a variety of DC applications, they offer resistance to metal transfer.